Overview

Seed count and population display for planters, seed-flow/blockage monitoring for air drills, granular fertiliser flow control, hopper level control, shaft rotation guard, fan rpm, hectare counter, tramline regulation – all in one instrument!

The robust, versatile device aimed for use all year round. Integra is capable to process and display the performance of 128 rows at a time on its large illuminated graphic screen. Integra was designed to best fit user’s demand with handy operation and easy survey of seeding process. Two i-LiNE ports enable monitoring of different application rates for seed and fertilizer rows. Easy operation is ensured by direct keys and control LEDs.

System Features

- Seed count/Fertiliser/Insecticide flow rate/blockage monitoring on planters

- Seed-flow/blockage monitoring of 3 products on pneumatic and some mechanic drills

- Full-featured seeding control program for planters up to 24 seed rows + 24 fertilizer/insecticide rows

- On-the-go calibration of expected seed density

- Manual or automatic speed tracking

- Tramline regulation (symmetric or asymmetric rhytms)

- Row closure motor/actuator end position control

- Hopper level display with low level alarm

- 2 rotation guards (one channel with numeric display, e.g. fan r.p.m.)

- Detection and display of blockages or dust accumulation on seed sensors

24

SEED ROWS MONITORING

3

PRODUCTS MONITORING

2

SECONDS BLOCKAGE DETECTION

High Rate Seed Sensor – DS1000i (Mounted on Seed Tube)

DS1000i seed sensor are made to count dropping or blown seeds on precision planters. 3-channel, high rate optical sensors, fine-tuned by seed shape and seed size settings, enable reliable detection of double/triple seed drops or skips. Each optomodule possess an intelligent processor unit run by microcontroller. Linear connection and interchangeable sensor sequence make installation easy in short time.

Sensor Features

- Seed count, seed-flow/blockage detection

- Detection and display of dust accumulation on seed sensor or blockage (DDC)*

- For planters 4-24 rows

- Mounted on seed tube

- Accurate seed detection with 3 infras

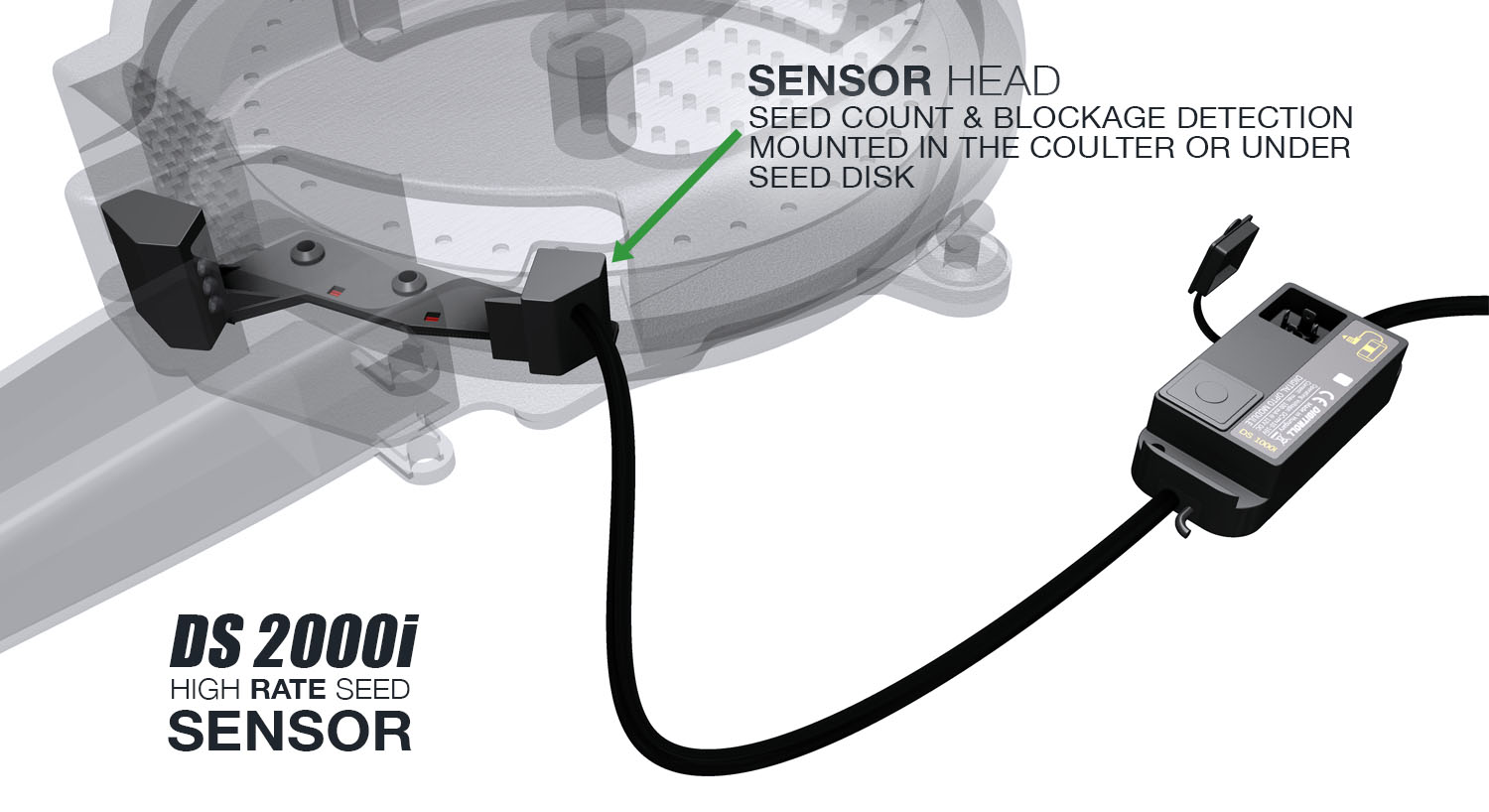

High Rate Seed Sensor – DS2000i (Mounted in the Coulter or under Seed Disk)

DS1000i seed sensor are made to count dropping or blown seeds on precision planters. 3-channel, high rate optical sensors, fine-tuned by seed shape and seed size settings, enable reliable detection of double/triple seed drops or skips. Each optomodule possess an intelligent processor unit run by microcontroller. Linear connection and interchangeable sensor sequence make installation easy in short time.

Sensor Features

- Seed count, seed-flow/blockage detection

- Detection and display of dust accumulation on seed sensor or blockage (DDC)*

- For planters 4-24 rows

- Mounted on seed tube

- Accurate seed detection with 3 infras

Tech Specs

System Components:

- Monitor: Seed Master Integra

- Seed Sensors: DS 1000i / DS 2000i

- Fertiliser/Microgranulate Blockage Sensor: DSGR 4000i

- Speed Module: DA 02i (wheel signal receiver)

Accessories:

- Tramline Regulation Module: Di2000

- Seeder Function Sensors Module: Di4000

- Sensor Type: Photocell

- Seed Sensors: DS 1000i / DS 2000i

- Standard Sensing Objects: seeds (eg.: maize, oilrape, sunflower)

- Minimum Detectable Object size*: 1-2 mm

- Maximum Speed of Detectable Objects: cca.15m/s

- Optical Detection Elements: 3-pair

- Detection proccess: Digital Signal Procession

- DDC – Automatic Dust Compensation**

- Cleaning Alarm: Automatic – send alerts if the sensor optics surface dust is too high**

*The minimum detectable object or particle size is depends on the objects or particles speed and the sensors optical elements dust status.

**Sensor cleaning is rarely due, thanks to Dust Detection & Compensation (DDC) function, so the operator can seed large areas without cleaning the sensors, allowing him to get the most out of the short seeding time at optimum conditions. The cleaning alarm is an unmatched solution to determine sensor dust level, then Dust Compensation, relying on dust test information, automatically compensate the sensibility. High sensitivity of blockage detection will be maintained by this solution. This solution is a Patented Technology by Digitroll.

- Sensor Type: Photocell

- Blockage Sensors: DS4000i / DSGR4000i / DSmGR4000i

- Standard Sensing Objects: seeds, granular fertilisers, microgranulates

- Minimum Detectable Object size*: 1-2 mm

- Maximum Speed of Detectable Objects: cca.25m/s

- Optical Detection Elements: 4-pair

- Detection proccess: Digital Signal Procession

- AdC – Automatic Dust Compensation**

- Cleaning Alarm: Automatic – send alerts if the sensor optics surface dust is too high**

*The minimum detectable object or particle size is depends on the objects or particles speed and the sensors optical elements dust status.

**Sensor cleaning is rarely due, thanks to Dust Detection & Compensation (DDC) function, so the operator can seed large areas without cleaning the sensors, allowing him to get the most out of the short seeding time at optimum conditions. The cleaning alarm is an unmatched solution to determine sensor dust level, then Dust Compensation, relying on dust test information, automatically compensate the sensibility. High sensitivity of blockage detection will be maintained by this solution. This solution is a Patented Technology by Digitroll.

- Display: High contrast graphical LCD display 4,7”

- Backlighting: LED backlight

- Soft Keys: 4 soft keys

- Quick Keys: 7 quick keys for monitor modes

- Microprocessor: Microchip

- Operating Voltage: 10 .. 24 VDC Diagnostic

- Status LEDs : 16 LEDs for quick diagnostics

- Operating Temperature: -20 .. +70 °C

- Storage Temperature: -30 .. +80 °C

- Protections: Overcurrent and Polarity Reversal Protection

- Dimensions (W x H x D): 225 x 140 x 35 mm